Wood

The wood industry is working to address the challenges it faces and to ensure its long-term sustainability.

The Wood Industry: A Major Economic Force

The wood industry is a major economic sector in many countries around the world. It encompasses the entire process of converting trees into wood products, from forestry and logging to manufacturing and distribution. The wood industry provides jobs for millions of people and generates billions of dollars in revenue each year.

The wood industry has a long and storied history. Humans have been using wood for shelter, tools, and other purposes for centuries. The first wood products were likely made from fallen trees, but the development of sawmills in the 18th century made it possible to produce wood products on a much larger scale.

The wood industry experienced rapid growth in the 19th and 20th centuries, as demand for wood products increased. Wood was used to build homes, furniture, ships, and other structures. It was also used to make paper, textiles, and other products.

The wood industry has faced some challenges in recent years. One challenge is the increasing competition from other materials, such as plastics and metal. Another challenge is the need to manage forests sustainably. The wood industry is working to address these challenges by developing new technologies and practices that are more environmentally friendly.

Despite the challenges, the wood industry is still a major economic force. It is expected to continue to grow in the coming years, driven by demand for wood products in developing countries and the need for sustainable materials.

Industry applications of wood:

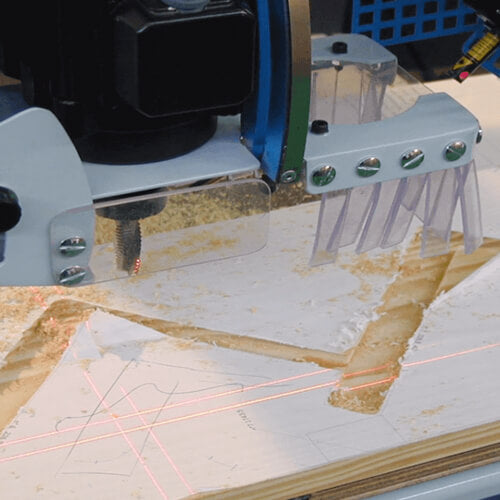

Laser Applications

The use of laser technology is particularly widespread in the wood industry. Whether precise line lasers for displaying cut and sawed edges, processing lines or for aligning workpieces, to the use of laser projectors to visualize individual work steps. The result is faster and easier work steps, more precision and less scrap.

Read MoreLaser Projectors for Gluing Tables – CNC-BAZ – Cutting Saws

Laser projectors are used to display the block size on the gluing table in its original scale. In this way the selection of suitable raw material is supported. The correct positional display of material and vacuum suction cups prevents milling cutter-incurred damage during processing.

Read MoreGlue Binders

Laser projectors form the shape of the future truss or framework. The tension struts are positioned in the glue bed. The quantity of lamellar material can be precisely determined this way.

Read MoreTruss Binders – more efficient with Laser Projectors

The laser projector creates a laser image from the truss binder design files in the original scale and maps this to the work surface. It projects the precise positions of the pressing blocks, the nail plates, and the wooden planks.

Read MoreSaw Blade Alignment

In this application two Laser Distance Sensors are mounted on each end of an extrusion to measure the difference in distance to the saw blade.

Read MoreHere are some of the key products and services of the wood industry

Lumber

Lumber is the most common wood product. It is made from sawed logs and is used to build houses, furniture, and other structures.

Plywood

Plywood is made from thin layers of wood that are glued together. It is stronger and more stable than lumber and is used for a variety of applications, including flooring, subflooring, and cabinetry.

Paper

Paper is made from wood pulp. It is used for a variety of purposes, including writing, printing, and packaging.